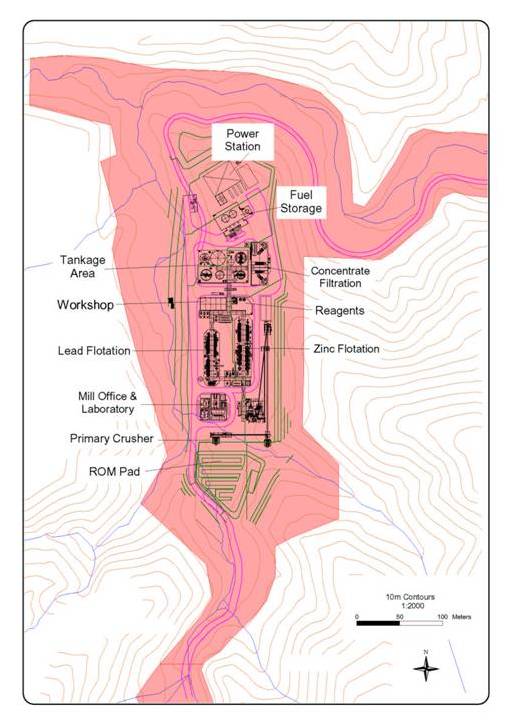

Processing Plant

The plant and equipment for a one million tonnes per annum (Mtpa) ore processing plant equipment is in storage and care in Medan awaiting fabrication at the mine site. The plant is designed to produce high grade zinc and lead sulfide concentrates at the rate of up to 225,000 tonnes of zinc sulfide and 105,000 tonnes of lead sulfide per annum.

After trucking from the underground workings to a run of mine (ROM) storage area, ore will enter the plant for processing. Here is a flowsheet of the DPM Ore Processing Plant. The processing stage will commence with the ore undergoing single stage jaw crushing, semi-autogenous grinding (SAG) and ball milling, flotation, thickening, filtration and drying.

Much of the bulk tailings from the processing plant will be sent to a paste plant for blending with cement to form a paste which will be injected back underground as backfill for empty mine workings. The remaining tailings will be sent to a tailings storage facility (TSF) located around two kilometers from the plant site. Electricity for the site will be supplied by a third party with the power originating from a geothermal source. Emergency backup power will be provided by five megawatt (MW) diesel driven generators located at the plant site.

The processing plant and supporting area will be constructed in three clusters: the main process plant containing the primary crusher, grinding, concentrate and thickening circuits; the filter and concentrate load out storage buildings; and, the administration buildings, stores and lay down areas.

Transportation & Shipping

In early production times, the dried zinc and lead sulfide concentrates will be loaded into fully enclosed purpose-built bulk containers and transported by road to a port at Kuala Tanjung around 240 kilometers from the minesite on the north east coast of Sumatra and 100 kilometers ESE of Belawan, which is the general commercial shipping port servicing Medan. The containers will then be unloaded and stored prior to loading into bulk sea carriers by way of a purpose-built ship loader. Currently, a study is being conducted on the feasibility of transporting concentrates in a slurry pipeline from the minesite to a ship loading facility in the Singkil area on the south west coast of Sumatra.

Piling for the port at Kuala Tanjung has been completed on the shore side for concentrate storage buildings and pile caps at sea have been partly constructed. The bulk of the mechanical port handling equipment including the wharf conveyor is stored at the port site.