General

The Anjing Hitam underground zinc mine development, after dilution, will recover 5.88 million tonnes of ore at around 25.3% per tonne zinc equivalent, with grades of 14.3% per tonne Zinc Sulfide, 8.8% Lead sulfide, and 11.3 grams per tonne Silver. Current underground mine life of the Anjing Hitam ore body is just over 8 years.

Mine Planning

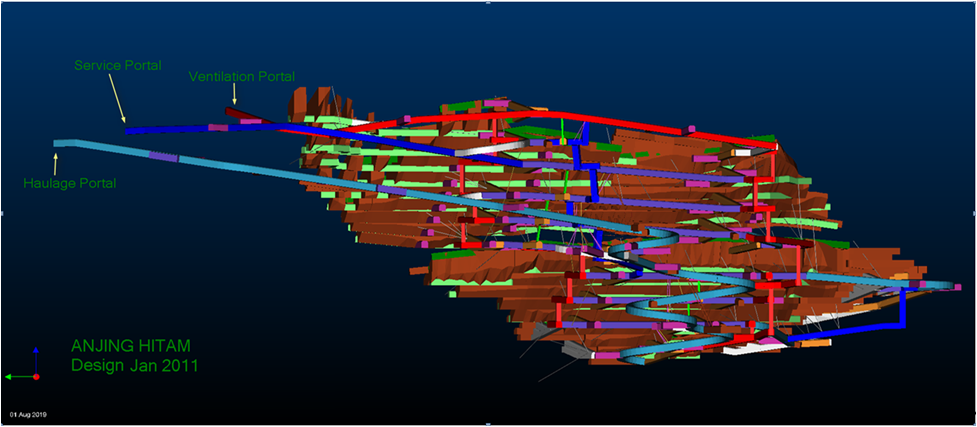

There will be three portals: haulage, service and ventilation. The portals will be accessed via a surface haul road and mined conventionally (drill and blast). Mining methods will be mainly long hole open stoping, primary-secondary longitudinal bench stoping and cut & fill.

Mining voids will be filled with paste fill which will prevent subsidence, maximize resource recovery and limit the size of the tailings storage facility (TSF). Ore and waste will be trucked to the surface via the haulage decline to a run of mine (ROM) ore transit storage area. From the ROM, Ore will be sent to processing plant for crushing and processing.

Waste rock will be used for the backfill of avoids in the mine and for the construction of the TSF. Ground support will be a combination of bolts and mesh, shotcrete/fibrecrete, cable bolting, rock fill and paste fill.

The ventilation circuit will consist of two (2) fresh air intakes via haulage and service portals and a series of rises to bring fresh air to the production areas. Exhaust is via a parallel system of ventilation rises and drives connected to the ventilation portal.

Water management will consist of development sumps, transfer sumps and pumps, including a main pumping station and a surface settlement pond.

Following is an example of 3D modelling used by DPM in its underground mine development planning:

Equipment

Major pieces of the new underground mining fleet are currently stored under maintenance in Medan awaiting the start of mine development: